What is an airless sprayer?

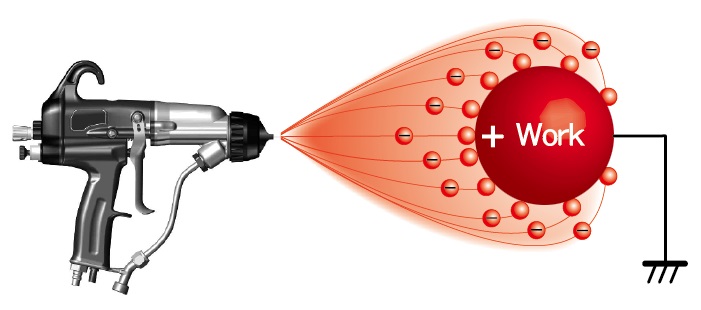

An airless sprayer is a pump that transfers paint under high pressure (usually around 3000-3300 psi) via a high pressure paint hose (usually about 15m long) to a spray gun. When the trigger is pulled on the airless spray gun, fluid is released through an airless spray tip or nozzle which breaks up the fluid into small droplets (atomization) without the use of compressed air. The airless spray tip size will determine the paint flow and the spray pattern width.

Airless sprayers are mainly defined by three main categories:

1) Diaphragm Airless Sprayers

Diaphragm airless sprayers use a hydraulic piston to draw hydraulic fluid from the sump and then compress the hydraulic fluid under a plastic diaphragm. The diaphragm pulses up and down causing the suction valve above the diaphragm to open and close, this creates enough suction to draw paint product through the suction hose. Once the paint has passed through the suction valve it enters the outlet valve which usually contains a ball and seat or check valve. This allows the paint to exit the outlet valve but does not allow pressure in the hose to push back through the outlet valve.

Diaphragm airless sprayers are controlled by a pressure control valve which regulates the rate of which the hydraulic fluid is released from the piston block back into the oil sump.

Diaphragm airless spray pumps can be driven by AC Electric motors and petrol/gasoline motors with a simple eccentric bearing on the end of the crankshaft, the bearing pushes the hydraulic piston up and down compressing hydraulic fluid under the diaphragm.

Diaphragm airless pumps are more common in countries that use 220/240v power such asIreland,Germany,Japan,ChinaandAustraliato name a few. In countries where the power grid only supplies 110v, diaphragm airless sprayers have only been popular in low capacity machines.

Diaphragm airless sprayers are a simple mechanical type of airless sprayer that has no electronics such as computer boards and sensors. In terms of use they will deliver paint out of the spray tip in exactly the same fashion as a piston airless sprayer.

2) Piston Airless Sprayers

Piston airless sprayers use a double acting pump in order to draw the paint from a container, this double action allows the pump to draw and transfer paint at the same time by using an inlet valve (foot valve) at the bottom of the pump and an outlet valve in the piston rod.

Once the airless pump is running the fluid is transferred in a continues flow through a small hose usually to a high pressure filter fixed to either the pump and motor or frame of the airless sprayer, this filter traps any small particles of debris or rubbish in the paint that could potentially block the airless spray tip.

The pressure of the airless sprayer is regulated by an electronic sensor that tells the motor when stop and start according to either the pressure selected by the operator or the maximum pressure setting default of the computer. Piston airless sprayers these days have complex computer boards that not only tell the machine when to stop but they can also adjust the speed of the motor depending on the size spray tip selected by the operator.

Electronic Piston airless sprayers are driven by DC Motors, although these motors are light and produce high torque they require more components than a diaphragm machines such as computer boards, pressure sensors and electronic pressure control. Piston machines are very popular in theUSAbecause the DC Motors used can produce more power on a lower power grid such as 110v.

3) Pneumatic or Air Driven Airless Sprayers

Pneumatic Piston airless sprayers use a double acting pump in the same manner as electronic piston airless sprayers but the drive unit is an air driven motor. Air driven motors are a simple reciprocating motor that works on basic resistance of the air pressure in the motor versus the pressure in the fluid pump.

Pneumatic airless sprayers are usually classed by the ratio of the air pressure fed into the pump air motor which determines the fluid pressure that flows out of the pump. To give an example of how this ratio is applied to the size of the pump, see below:

30:1 Ratio Pneumatic Airless Sprayer

Fluid Pressure 30psi for every 1psi of air pressure fed into the air motor. If the air motor inlet pressure was regulated to 50psi, the fluid pressure in the pump would be 1500psi (50psi x 30psi = 1500psi)

Pneumatic airless sprayers are used mainly for industrial type coatings were possible electrical hazards exist such as in steel manufacturing or applications were electrical supply is limited or not available. Pneumatic airless sprayers are also useful for thicker industrial coatings that require higher atomization pressure at the spray tip. Electric piston machines do not exceed 3300psi but pneumatic airless sprayers can spray up to 8000psi.

How are airless sprayers rated:

1) Tip Size - Most airless sprayers will have a specification of "Maximum Tip Size", this specification is the largest size tip that the airless sprayer can support to maintain a reasonable working pressure. If you were to fit a larger tip than the maximum size rated for the airless sprayers you will find that the pressure drop when you squeeze the trigger on the airless sprayer hand gun will be much larger than the machine can handle and the finish may be distorted or produce "tails" at the top and bottom of the spray fan.

Most of the major brands of airless sprayers are conservative with the maximum tip size recommendation but some companies in the past have rated airless sprayers by tip sizes that don't exist such as 0.022". No company produces a 0.022" thou tip, you can either buy a 0.021" tip or a 0.023" tip, this is purely marketing in a cheap bid to "out-do" a competitors brand of airless sprayer when comparing brochures side by side.

2) Flow Rate - This is measured in US Gallons or Litres Per Minute, this is the best way to identify which airless sprayer has the most output. The greater the flow, the easier the machine works, so buy the airless sprayer with the highest amount flow where ever possible.

3) Motor Size - Judging an airless sprayer by the motor size is probably the wrong way to work out which airless sprayer is best. In piston electric airless sprayers, DC motors have advanced considerably since the old days, smaller motors are producing more torque and with brushless DC motors they come in all shapes and sizes. The best method to identify the airless sprayer that suits your requirements would be to consider the maximum size tip and the flow rate. Don't be too concerned with the size or specifications of the motor of an airless sprayer.

Advantages of using an airless sprayer:

Airless sprayers provide an easy and economical way to apply coatings. Professional contractors prefer to use airless sprayers for many reasons, the most popular being:

1) Speed - airless spraying is faster, thus, more jobs can be completed in less time, using less labour. Airless spraying is up to 4 times faster than brushing or rolling.

2) Quality - airless sprayers produce an even coat of paint on all types of surfaces, leaving a high quality finish.

3) Versatility - airless sprayers can be used for a wide range of coating materials, including interior and exterior jobs, and can easily be transported from job site to job site.

FAQ's about Airless sprayers:

1) Question - Can an airless sprayer be used to spray a car?

Answer - No, airless sprayers air unsuitable for automotive applications, the flow of material or paint is too high and the finish would not be satisfactory. Automotive spray painting is best done using an air compressor and air spray gun.

2) Question - Can an airless sprayer be used as a water blaster or high pressure cleaner for cleaning driveways etc?

Answer - The average airless sprayer would be unsuitable for use as a high pressure water blaster because the average machine would not have enough water flow to be an effective cleaner. Using an airless sprayer as a water blaster would lead to premature wear of the seals and components.

3) Question - Do I need to thin the paint to spray with an airless sprayer?

Answer - Generally no, thinning would only be required if you wanted to change the finish of the spray, some painters may thin the paint to produce a 'stipple" type of effect in the spray finish but thinning the paint in general terms will simply reduce the coverage of the paint on the surface.

4) Question - How much faster is applying paint with an airless spraying against brush and rolling?

Answer - In general terms, applying paint with an airless sprayer is considered approximately "four times faster". This is not to say that you will not need to brush and roller, applying coatings with an airless sprayer is usually used at the beginning of a project, to apply the undercoat and base coats, finishing some areas with a brush and roller will still be required.

5) Question - How long will an airless sprayer tip last before it is worn?

Answer - The life of an airless sprayer tip will vary between coatings, but an airless sprayer tip is considered to last for between 500-1000 litres of paint before being worn to the point that it should be replaced.